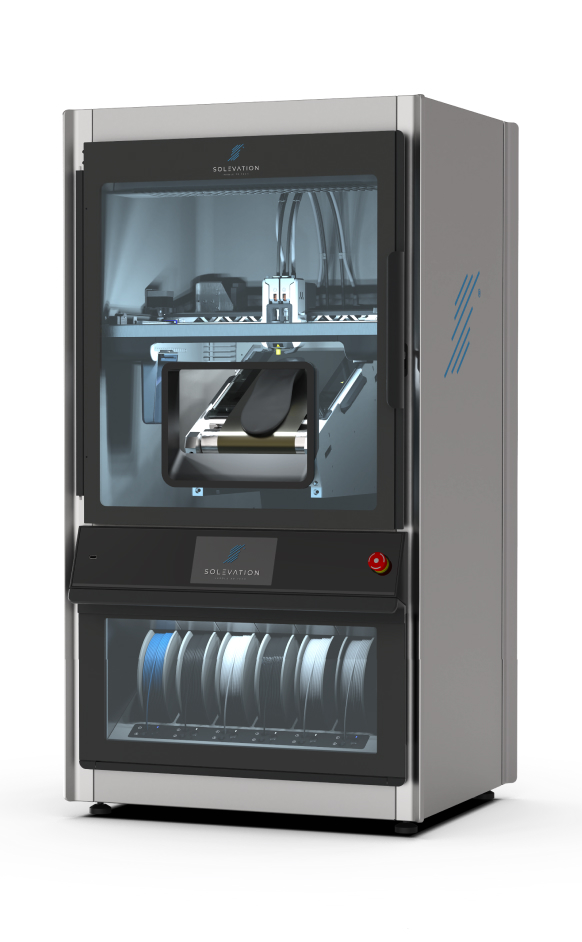

Premium 3D-Printer for Insoles

SOLEVATION:

The Ready-to-Use Solution for Custom Insole Production

- 24/7 precision manufacturing of custom orthopedic insoles

- Minimal post-processing time

- Capability to combine multiple material types

- Made in Europe, adhering to the highest quality standards

- Plug-and-play ready, no prior 3D printing expertise required

Features

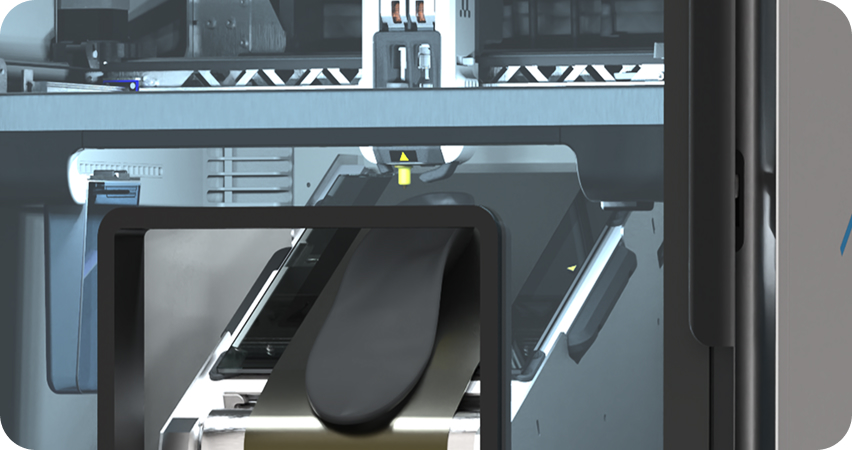

The Fastest of Its Kind

Compatible System

Seamless integration with existing CAD systems and 3D scanners.

24/7 Autonomous Production

Maximum operational continuity enabled by fully autonomous manufacturing.

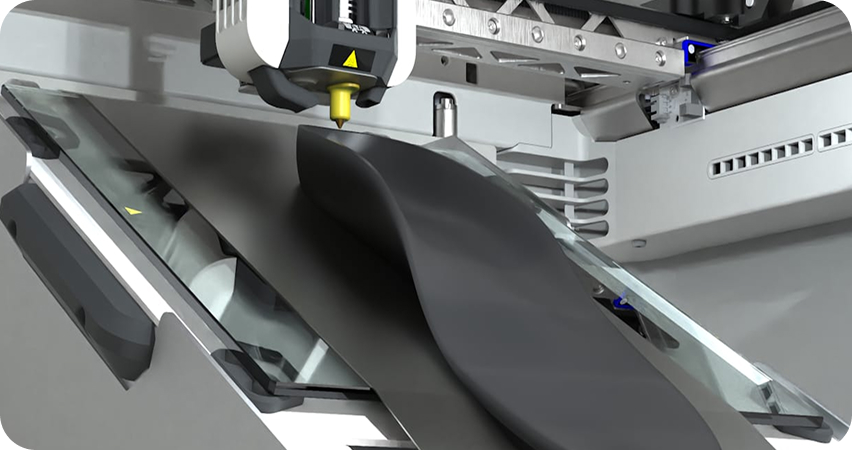

Multi-Material 3D Printing

Capability to combine multiple materials per insole.

Safe and Clean Operations

3D printing operates dust-free, quietly, and safely, promoting a healthier working environment.

Quality Test

Seeing Is Believing! Test It Yourself!

Order Your Free 3D Printed Custom Insole Now.

SOLEVATION is designed to maximize the (therapeutic) value of custom insoles. Curious to see how your design turns out from the printer? Discover the precision for yourself and feel the difference. Upload your STL file and receive a tailor-made insole, free of charge and without any obligations.

"*" indicates required fields

Process

How Does The System Work?

Minimum Effort, Maximum Output.

Discover the new standard in orthotic insole production, designed for minimal effort on the manufacturing side and maximum added value for the end user. Scan, design & print: achieve results in just 4 steps.

3D Footscan

Create a 3D model of the foot in seconds with a 3D foot scanner. You can use your own existing scanner or the special SOLEVATION scan model. Receive STL files, analysis reports, and detailed photos.

Design

Refine the insole using your own CAD software or ours. Choose parameters or utilize a library filled with ready-made models.

Load the filament, press start, and SOLEVATION takes care of the rest—fully autonomously.

Finish

Customize the final details such as colors, covering, and top-layer materials. Precision and personal comfort go hand in hand.

One Printer,

So Many Possibilities

3D Printer for Foot Orthotics

Average production of

75

pairs of insoles per week

Dimensions: 695 x 605 x 1287 mm

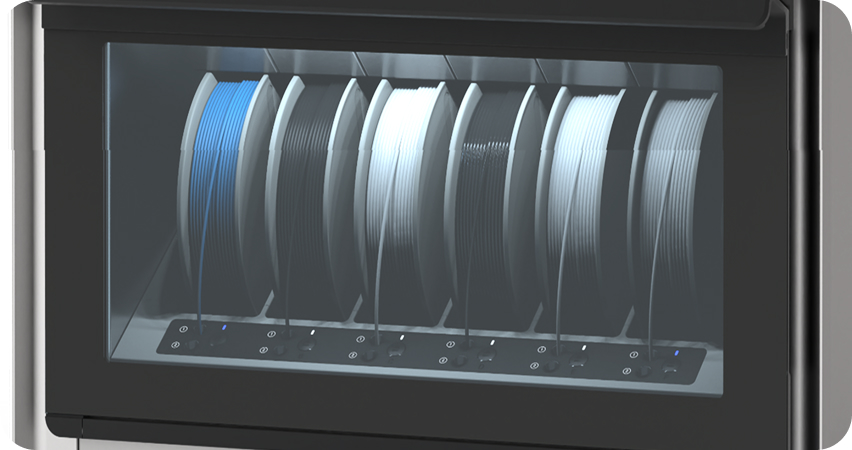

- One integrated touchscreen control panel

- Simultaneous loading of 6 filament spools

- Remote monitoring via built-in camera

The Full Guide to

3D Insole Printing

Download our brochure for a deep dive into SOLEVATION’s tech and features.

"*" indicates required fields

FAQs

Your Questions About Our System

Find quick answers to the most common questions or head to our FAQ page to dive deeper.

What makes SOLEVATION different from traditional insole manufacturing?

With SOLEVATION, you can deliver a ready-to-use final product instantly to your client. Unlike CNC milling, SOLEVATION ensures zero material waste, making it an efficient and eco-friendly choice.

Can I use my own CAD software with SOLEVATION?

How long does it take to print a pair of insoles?

It takes approximately 1 hour per insole on our printer — depending on their size, density and the type of printer used.

What type of material can be used with a SOLEVATION printer?

SOLEVATION utilizes a specialized foaming TPU available for purchase on our website. Please note that using any other material in the machine is prohibited due to quality and warranty concerns.

What support does SOLEVATION offer?

We offer education about how to use our software and are having both software and hardware engineers available to deal with after sales services.

Let’s Build Better Footwear Together

Get in touch with our team to learn more about SOLEVATION’s products, rental options, filament refills as well as support services.

"*" indicates required fields